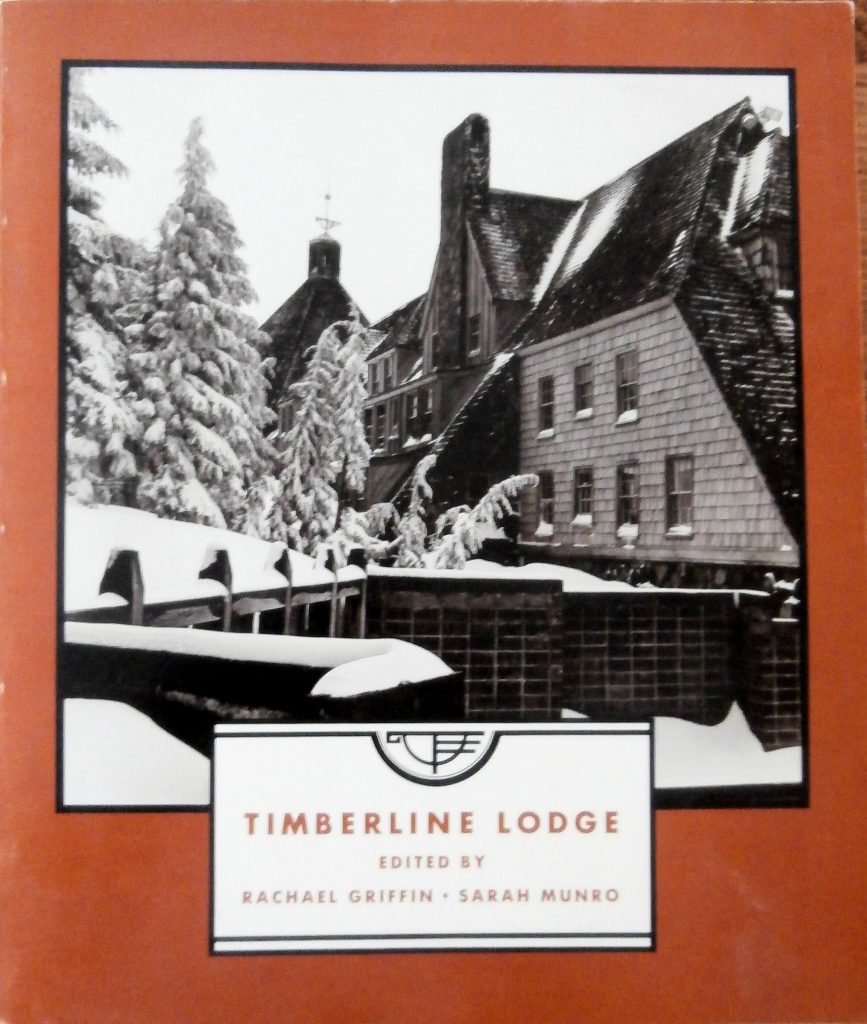

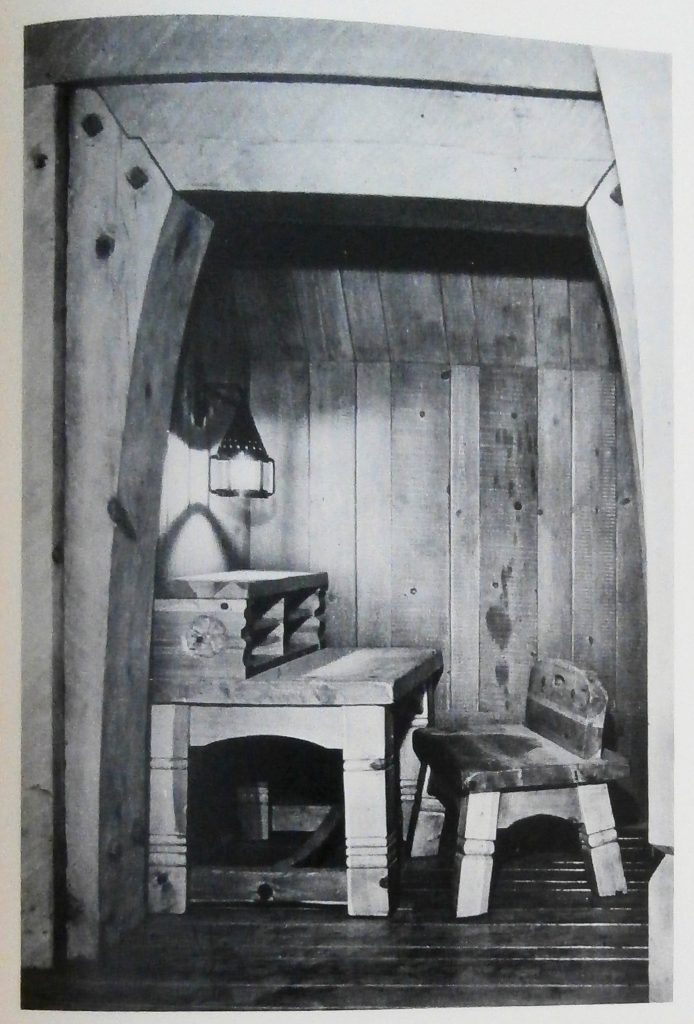

Not long after moving to Eugene, Oregon in 1987, I traveled to Timberline Lodge on the slopes of Mt. Hood to take photographs and measurements of what are known as the Mezzanine Desk and Chair, part of the of the original 1930’s Depression era collection of furniture made by WPA (Works Progress Administration) artisans for the lodge. I did that so I could make an exact reproduction of the two pieces. Below you see a picture of the cover of a book on Timberline Lodge published by Friends of Timberline in 1978 and a photograph from the book of the original desk and chair in one of the alcoves on the lodge’s mezzanine level.

My reproduction differed from the originals in two repects: one, I used clear vertical grain (CVG) Douglas fir while the originals are made of Douglas fir with knots; and two, I made rubbings of the carved five-petal flower on either side of the upper portion of the desk in order to replicate the carvings on my reproduction.

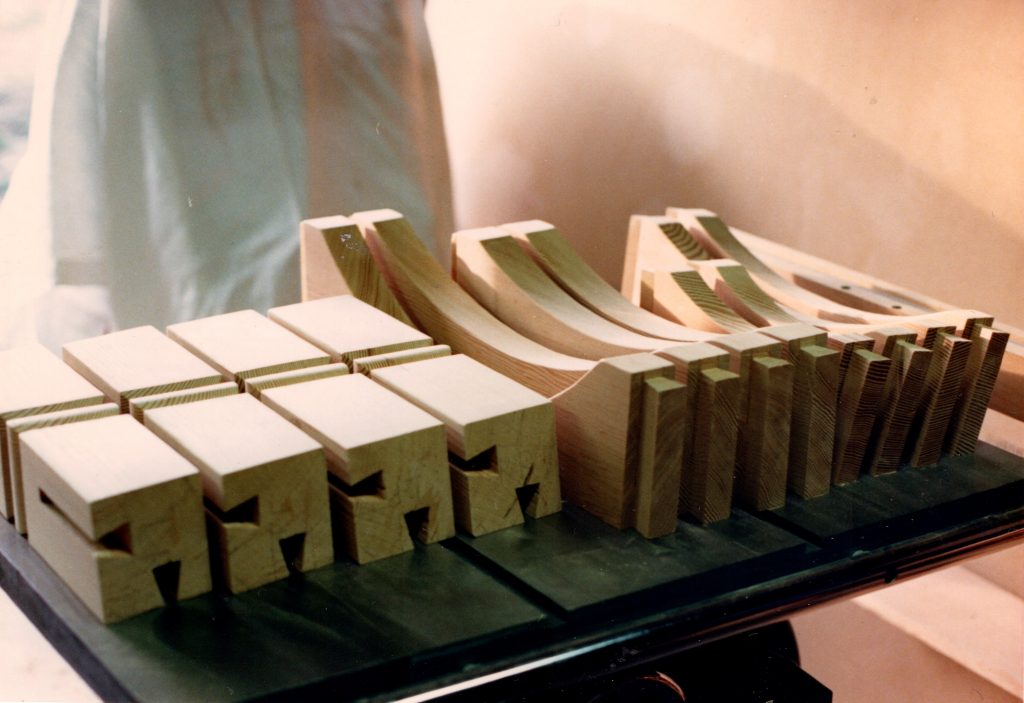

With no plans to guide me on the actual construction of the heavy-timbered desk and chair, I settled on what I thought would be the most durable way to secure the leg and stretcher sets for both, and that is through the use of sliding dovetails. Although I do not believe this is the technique used on the originals, it made the greatest sense to me because of the fact that both leg sets are splayed outward creating compound angles where the legs connect to the skirts and the stretchers, as you can see in the photograph above. The desk legs were approximately 4″ x 4″ square and the chair legs were approximately 3.5″ x 3.5″ square. Constructing the legs sets so that the splay angles matched those I had measured in the originals was a challenge, involving the use of the traditional sliding T-bevel. Below you can see the leg set for the chair, and the skirt sets for both the desk and chair, prepared for assembly with the dovetail slots and keys.

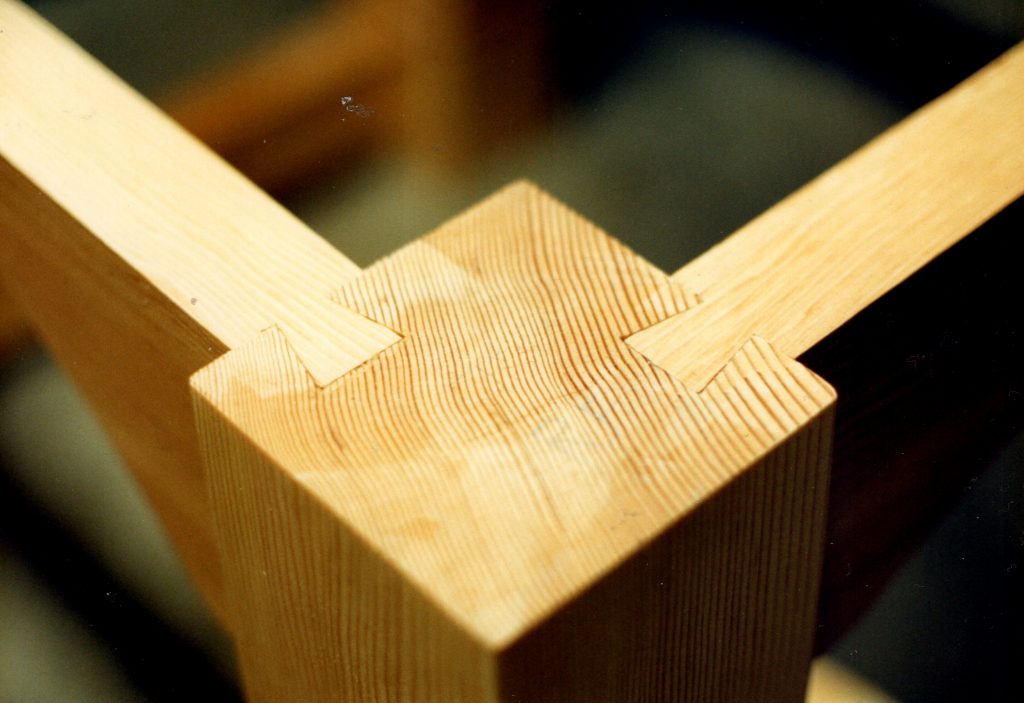

In the next two photos you can see a detail of how the skirt pieces are joined to a leg, and then the fully assembled leg set for the desk.

The rounded profiles on all four legs of the desk and chair were created prior to assembly by rough cutting the profile one leg at a time on the bandsaw and then finishing by hand with wood rasps, files, and what are called wood “floats,” and finally sandpaper.

The pieces for the desk top, the seat and back for the chair, and the upper section of the desk were all worked with handplanes to create the smoothest surfaces, smoother by far than what is possible with sandpaper. Below you can see my use of a jack plane to refine the edge of the desk top.

The next photo set depicts the desk and chair assembled, with a detail of the chair back support, but prior to the application of any finish.

With a Minwax Natural sealer and a Watco Danish Oil natural finish, the set looked like this when new in 1987.

I used the desk and chair from 1987 until 2020 when I sold the two pieces and the 1978 Friends of Timberline book to a couple in Portland, OR. The wife in particular has a love of Timberline Lodge and has collected Timberline memorabilia, including commemorative Timberline Lodge blankets woven by the Pendleton woolen mills in Pendleton, OR, to display in one corner of her home. The couple have two children who use the desk now for homework. I could not have asked for a better home for my work. Here are two pictures she sent me of the desk and chair in their new home.