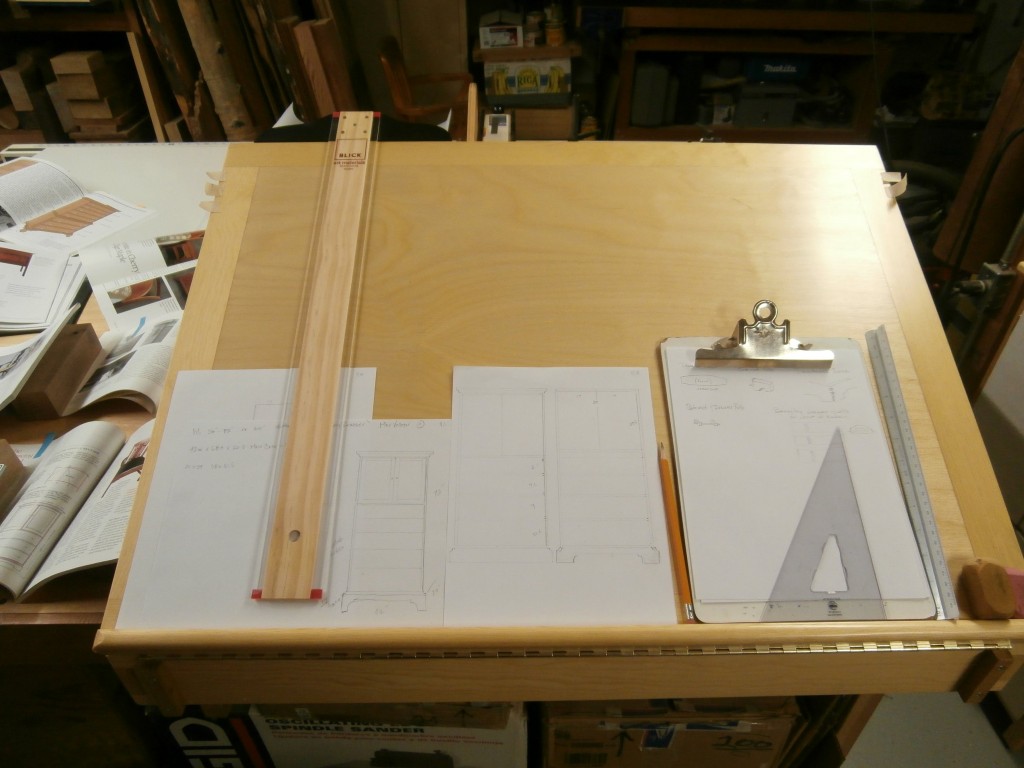

Today, I am starting in earnest on the design for my 6′ tall cherry dresser with 4 graduated drawers below and 2 raised panel doors at the top which will open up to 4 pull-out bin-drawers. To be made with knot-free, wide plank, black cherry lumber from Pocahontas County, West Virginia, that I’ve been air drying for over 30 years. (Click on any image to enlarge)

Big Leaf Maple Burl Bowl

Pots & Bowls

Weed Pots in February

This is what you can do with a weed pot/Ikebana vase in February. I clipped one branch each from my ornamental crab, ornamental plum, and Mountain ash trees in the back yard. The pot was turned from a “defect” in an otherwise clear Oregon black walnut board. (Click on the image to enlarge)

The walnut pot/vase by itself is 5″ tall, 1.75″ in diameter, and has a 5/8″ diameter slug of steel bar hidden in the base for stability.

Ikebana Vases

I have a hard time calling these weed pots, although that is their genesis. The one on the left is Wenge and the one on the right is in Adaman Paduak. They are drilled out and weighted with 5/8″ steel plugs on the bottom for stability.

I started turning utilitarian items (rolling pins, bowls, chair legs, etc.), but I’m starting to see the potential for sculpture. (Click on the image to enlarge)

Two White Oak Bowls

These two bowls were turned from two blocks of wood that were originally side by side in the same oak board, yet they differ substantially in appearance. The bowl on the right came from the center of the board, closer to the heart of the tree, and the one on the left was a little further from the center. The wood grain effects are noticeably different, and the coloring of the wood is slightly different. The curve of the sides varies slightly from one to the other, and the diameter of the bowl on the right is about one inch greater. Offered for sale together, a discerning buyer would have a clear choice to make. There’s no question which one I would pick. (Click on the image to enlarge)

New White Oak Bowl

I’m partial to this basic “containing” bowl shape and here it is in white oak. The oak has a nice warm brown tone when finished with just beeswax. I used another piece of oak to burnish the edge while the bowl was spinning on the lathe. (Click on any image to enlarge)

Rocking Chair Repair

I get more rocking chairs in for repair than any other piece of furniture. No surprise, really. They are favorites in most households and the very fact they are rocked back and forth thousands of time puts a strain, over time, on frames. This nicely proportioned solid oak rocker from the early 20th century was typical in that the original hide glue that held the joints together was nearing 100 years old and turning to powder, loosening all the parts. (Click on any image to enlarge)

My first step was to disassemble the chair as much as possible.

Then any missing or broken pieces are fabricated anew. Old finish is removed via stripping and/or sanding if the client requests it be done, as happened here . Then the chair is reassembled, in this case with new dowels and reconditioned seats for the dowels.

Free Hand Turning Vase Shapes

I’m considering trying to sell turned “weed pots,” made from various species of wood, in our local coop art gallery. First, I need to refine my technique for turning, drilling out, and finishing them and decide on a practical size or sizes. I also need to see how quickly I can finish one. (Click on any image to enlarge)

These examples are, from l. to r., 5″ tall in Claro walnut, 8.5″ tall in American black cherry, and 6″ tall in Wenge.

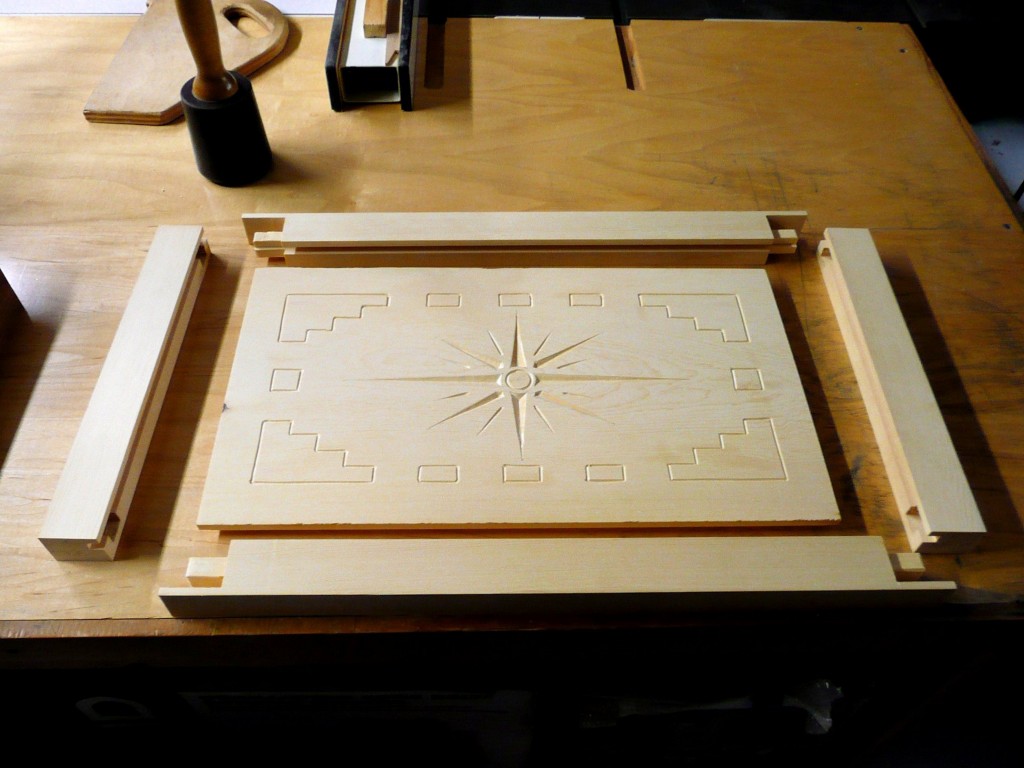

Hand Carved, Painted, Northern New Mexico Style Chest

This chest is my original design, utilizing carved detailing characteristic of 17th and 18th century chests from northern New Mexico around the Taos area. It is constructed of clear Ponderosa pine, the wood of choice for that area and time period. (Click on any image to enlarge)

The stepped motif in the four corners of the lid is a part of the southwestern pueblo iconography, and can represent either mountains or clouds. The next three photos show the chest in its unpainted state. All four sides of the chest employ true framed, hand planed, raised panels, with the front made up of two such panels.

In order to keep any wood end grain from showing on framing for the relief carved lid, I used some carefully executed joinery, with blind tenons as the main connective element. This and other refined details on this chest are not commonly found in the original more rustic chests of the 17th and 18th centuries.